Crystal series

CaF2 Product

Calcium Fluoride crystal shows good optical and thermo-mechanical properties, can be used for optical windows, lenses, prisms within a wide range from 130nm to 9μm. It has optical properties of isotropy, low absorption and low refractive index, which made CaF2 gain the unique advantages in the application of high power lasers.

Material: CaF2

Diameter Tolerance: +0.0/-0.02mm

Thickness Tolerance: ± 0.01mm

Surface Accuracy: λ/4 @632.8nm

Surface Quality: 60-40

Clear Aperture: > 90%

Bevel: 0.2mm×45°

Coating: user-defined

BaF2 Product

Barium fluoride crystal shows good optical transmittance over wide spectrum range, from 150nm to 12.5μm. It is used for windows, lenses and prisms, particularly for the application of ultraviolet transmittance. The highest quality of BaF2 has an application as the well know scintillation crystal.

Material: BaF2

Diameter Tolerance: +0.0/-0.02mm

Thickness Tolerance: ± 0.01mm

Surface Accuracy: λ/4 @632.8nm

Surface Quality: 60-40

Clear Aperture: > 90%

Bevel: 0.2mm×45°

Coating: user-defined

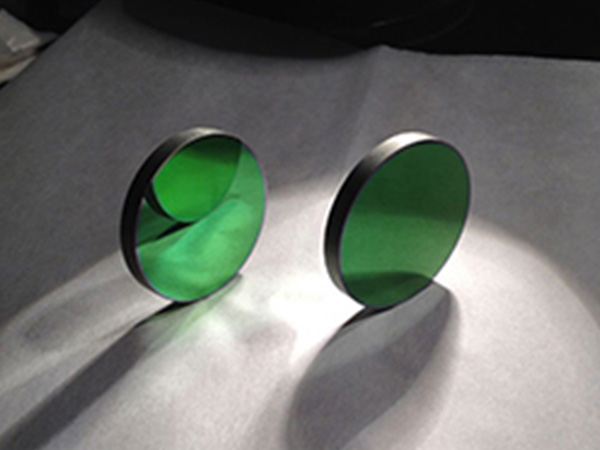

ZnSe Product

ZnSe is used for optical windows, lenses, mirrors, prisms and optical blanks, plates, disks, sheets, slabs particularly for infrared applications Zinc Selenide (ZnSe) — transparent in wide spectral range from yellow (visible) to far IR. ZnSe material is a chemically inert, non-hygroscopic and highly pure product that is very effective in many optical applications due to its extremely low bulk losses, high resistance to thermal shock and stability in virtually all environments, easily machined.

Material: ZnSe

Diameter Tolerance: +0.0/-0.02mm

Thickness Tolerance: ± 0.01mm

Surface Accuracy: λ/4 @632.8nm

Surface Quality: 60-40

Clear Aperture: > 90%

Bevel: 0.2mm×45°

Coating: user-defined

Sapphire Product

Sapphire is of high mechanical strength, temperature stability, wear resistance and chemical inertness.Sapphire Window exceeds other optical materials in harsh environments, providing a barrier between elements. Sapphire Windows are used commonly in optical and mechanical applications. We offer a wide range of Sapphire Window for customization.

Material: Sapphire

Diameter Tolerance: +0.0/-0.02mm

Thickness Tolerance: ± 0.01mm

Surface Accuracy: λ/4 @632.8nm

Surface Quality: 20-10

Clear Aperture: > 90%

Bevel: 0.2mm×45°

Ge Window

Germanium window has the advantages of high infrared refractive index, wide infrared transmission band, small absorption coefficient and low dispersion. Which is suitable for military and thermal imager, infrared radar and other infrared optical devices.

Material: Ge

Diameter Tolerance: +0.0/-0.02mm

Thickness Tolerance: ± 0.01mm

Surface Accuracy: λ/4 @632.8nm

Surface Quality: 20-10

Clear Aperture: > 90%

Bevel: 0.2mm×45°

Coating: user-defined

Silicon product

Silicon (Si) is grown by Czochralski pulling techniques (CZ) and contains some oxygen that causes an absorption band at 9 microns. To avoid this, material can be prepared by a Float-Zone (FZ) process. Optical silicon is generally lightly doped (5 to 40 ohm cm) for best transmission above 10 microns, and doping is usually boron (P-type) and phosphorus (N-type). After doping silicon has a further pass band: 30 to 100 microns which is effective only in very high resistivity uncompensated material.

Material: Silicon

Diameter Tolerance: +0.0/-0.02mm

Thickness Tolerance: ± 0.01mm

Surface Accuracy: λ/4 @632.8nm

Surface Quality: 60-40

Clear Aperture: > 90%

Bevel: 0.2mm×45°

Coating: user-defined

ZnS Lenses

Zinc Sulphide (ZnS) is used for manufacturing of infrared IR optics: ZnS windows, ZnS polished domes and ZnS lenses in spectral range (0.4 - 13.5) microns where maximum transmission and lowest absorption is required, and also selected for use where visible alignment is an advantage.

Material: ZnS

Diameter Tolerance: +0.0/-0.02mm

Thickness Tolerance: ± 0.01mm

Surface Accuracy: λ/4 @632.8nm

Surface Quality: 60-40

Clear Aperture: > 90%

Bevel: 0.2mm×45°

Coating: user-defined